Shakespeare have supplied a range of robust, cast airport landing light assemblies supplying most of the regions airports for the last decade. This and further examples of our experience in the Aerospace sector are shown below.

Runway Lights

Shakespeare has the ability to cast small, intricate components in batch quantities. As such, we have supplied hundreds of aircraft runway landing light assemblies, comprising of a housing as shown, and a cap. Shakespeare is also very experienced at casting small, batch volume components and as such has manufactured thousands of cast iron light adaptor and seating rings. The cast parts form an assembly which is inserted below ground and used to light up airport runways.

Aircraft Wing Tool

Like the Automotive industry, Shakespeare has supplied the Aerospace industry for a number of years, specifically in the manufacture of aircraft die tools and form tools.

The photo below shows a typical cast aircraft wing form tool, manufactured in a wear resistant material.

Engine Hub

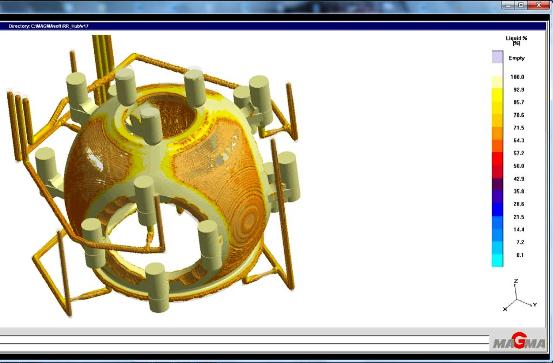

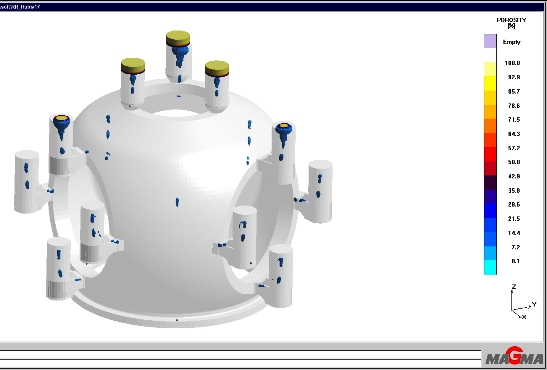

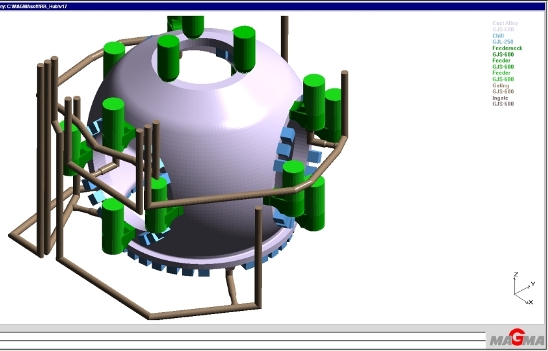

Shakespeare regularly engage with clients requiring high integrity castings. The following images illustrate the pre-casting process of an aerospace engine hub, which was used to ensure that we supply only the highest grade castings to our clients. We run all our sales order castings through a Magma analysis, which is a type of computation fluid dynamics analysis, reviewing the casting feeder design to eliminate porosity in the final product. Once the molten metal is poured into the casting feeder system, there is an idealised timescale in which it must cool and solidify. Cooling too fast or too slow can create undesirable grain structure and/or inclusions in the final cast product, hence our engineers target the "goldilocks-zone", refining the feeder design until idealised conditions are obtained. Clearly, after all the analysis, review and refinement, Shakespeare aim to produce inclusion-free products which meet and exceed client supply specifications and expectations. The image below is an extract of our Magma review process which accurately predicts where inclusions/defects will reside after the cast product is cooled.

Vertical Form Tools

Shakespeare supply a number of die tool and form tool castings to the Aerospace industry.

The photo above illustrates a vertical form tool used by the Aerospace industry in the production of aircraft components.